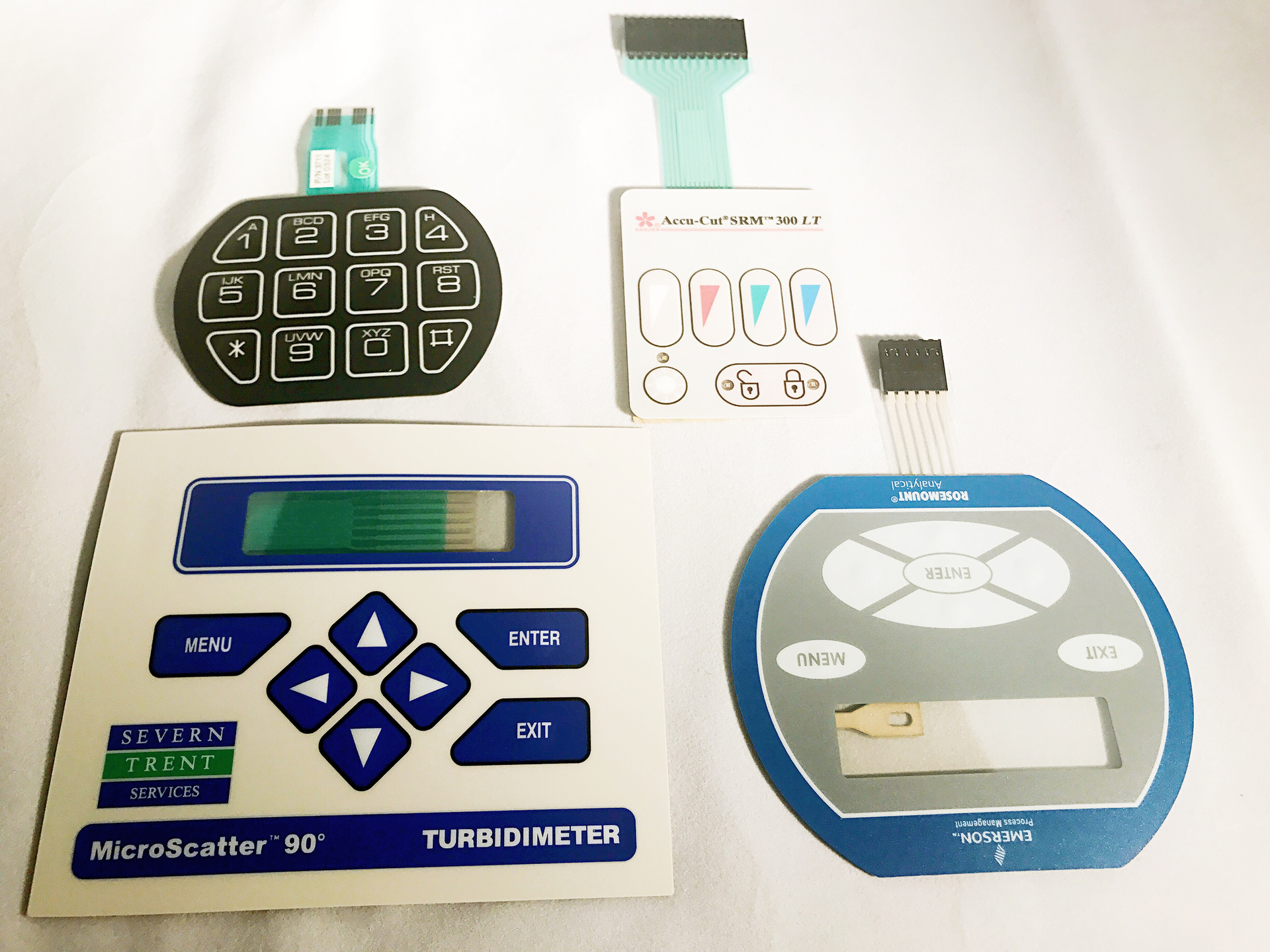

There are multiple types of power buttons; for instance, there are copper or plastic mechanical switches, which may have plastic, metal or rubber buttons on the outside. Then, there is the membrane switch; this is a momentary contact switch with touch sensitive characteristics, made possible by printed, cut and laminated precision thin film and plastic.

When fingertip touch is applied to the surface of this type of switch, there is a low voltage, low current that is activated so that the switch turns on or off. The interface is a smooth cover, typically comprised of a graphic overlay that may be flat or embossed. This interface is what the user makes touch contact with; the cover acts as a seal for the switch and protects it from being contaminated by indoor and outdoor elements.

Membrane Switch Keypads - Usage

These switches are primarily used on products that act as microprocessor based control systems found in medical devices, telecommunication systems, industrial instrumentation applications and household appliance products. Everything from a life-saving emergency room machine to a simple microwave oven can rely on membrane switches for their control panels. These switches offer many advantages in applications where sterility is imperative, because the sealed technology is widely known for being easy to clean.

The KEE Group USA Advantage

KEE Group, an international interface manufacturer with distribution operations in the United States, manufactures sealed membrane keypads and switches that are durable, environmentally sound and able to withstand high temperatures. We can furnish your products with switches that can hold up to temperatures of 221 degrees Fahrenheit. All of our sealed switches are designed to be waterproof, unless otherwise specified.

Types of Membrane Switches

The two most common types of membrane switch are:

Tactile –

Tactile membrane switches are more closely associated with traditional buttons because of their distinct “snapping” action, also known as “user feedback.” The most popular tactile variety is the conductive stainless steel snap dome; they also typically eliminate the need for a flexible upper circuit layer, which may be regarded as a cost benefit. To complete the design and ensure the longevity of the control panel, a backing layer is typically incorporated into the tactile switch. If a less impactful tactility is desired, the metal dome can be substituted with a polydome (polyester dome). Both are equally reliable.

Non-tactile –

Non-tactile switches are more common, for a variety of reasons. They are widely regarded as more reliable in terms of longevity, and are also more economical to produce because they contain fewer high end components (i.e. metal dome). The disadvantage that some manufacturers may see in the non-tactile variety is that users do not receive direct feedback (the “snap” mentioned above).

Fortunately, this is not an insurmountable problem. If user feedback is necessary, non-tactile membrane switches can be backlit with an LED, EL or fiber optic indicator so that a light displays when the switch is activated. And unlike tactile switches, non-tactile switches are able to be made in customized shapes and sizes. Many manufacturers appreciate this design flexibility.

Mixed panels – Mixed panels, which are keypads that combine both the tactile and non-tactile variety, are occasionally submitted as a customization request from our customers. Kee Group USA can certainly accommodate this demand when it is requested.